Workshop Automation and Robotics

CNC Turning

Two Hyundai Hiturn CNC turning centres - one with an 8-station toolpost, the other with a 12-station toolpost - together with a Hyundai SKT28 CNC slant-bed turning centre, gives us great flexibility when it comes to turned components - whether it be commercial small or medium-volume production or intricate short runs.

- 5 X CNC Turning Centres (2 X Hitrol 840C controlled + 1 X Fanuc 21i controlled)

- Maximum material size of 500mm diameter x 50mm billets

- Minimum material size of 2mm rod

CNC Milling

Our CNC milling capabilities include:

- 8 x CNC Vertical Machining Centres (all Heidenhain TNC controlled)

- Maximum material size of 1000mm x 500mm x 50mm

- Minimum material size of 2mm diameter (collet held)

We can machine complex components by integration of one of our eight CNC Turning and Vertical Machining Centres. The stainless-steel component above demonstrates a compound angled milled face set on a concentric turned flange.

A stable of seven modern Bridgeport VMC vertical machining centres and three CNC turning centres means we can produce high volumes of precision work on demand.

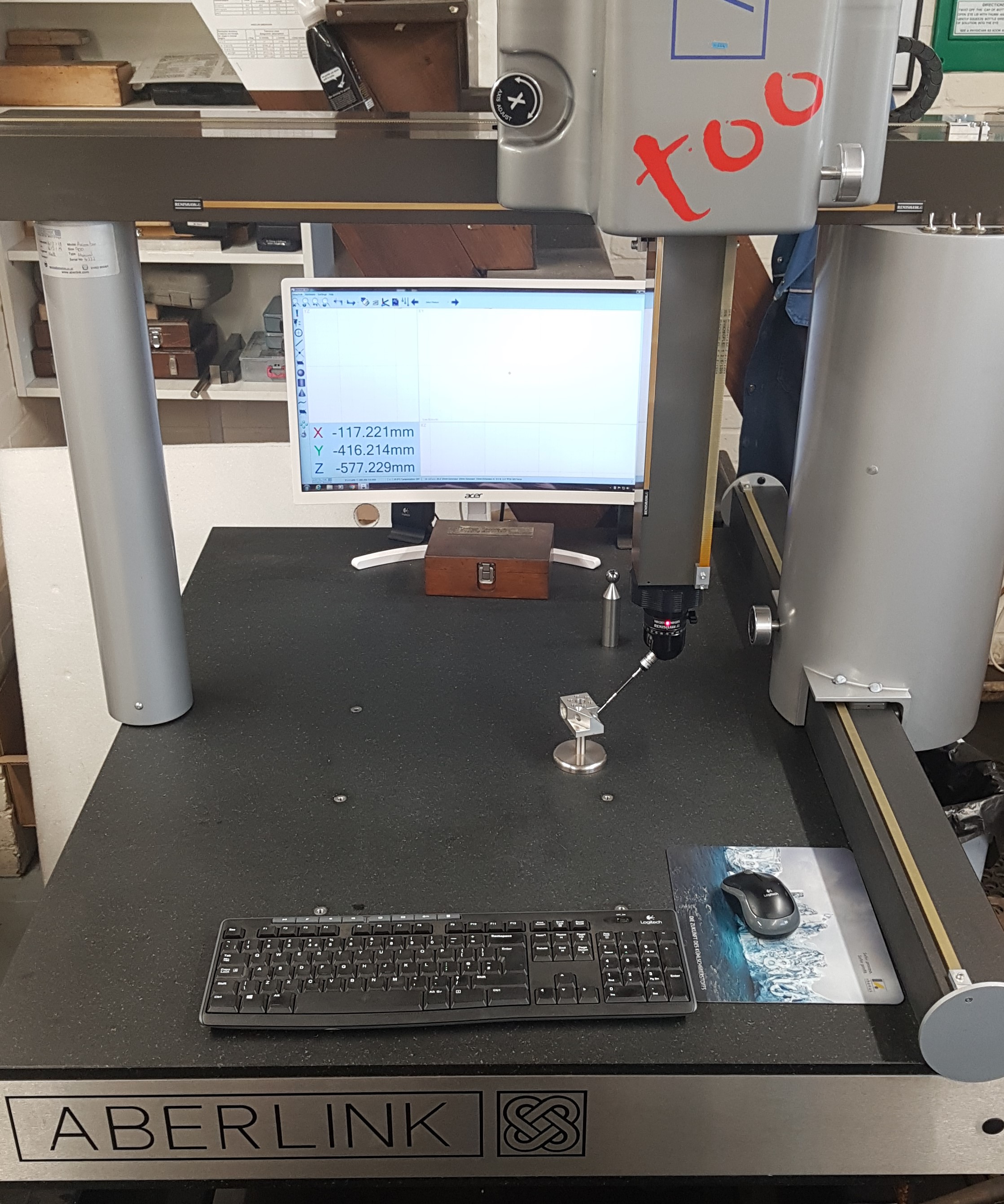

CMM Inspection

First Article Inspection

Guaranteed conformity to drawing specifications.

With an accuracy of 0.001mm we can supply an F.A.I. whatever tolerance you require.

Programming from 3D model

We can machine complex components from solid models with ONECNC XR7 CAD/CAM software.

Materials +

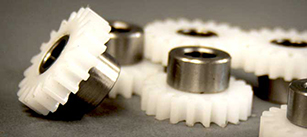

Compound Components

We are competent in pressing or bonding dissimilar materials together using a variety of methods from a mechanical press through to specialised bonding agents. The above example is a stainless-steel hub precision pressed into a nylon gear to maintain true concentricity between the two components. We are also able to machine an extensive array of materials some of which can be found below:

Metals

- Aluminium

- Magnesium

- All grades of Steel (Ferrous and Non-Ferrous)

- Brass

- Bronze

- Phosphor Bronze

- Gunmetal

- Copper

- Lead

- Gold

- Silver

Plastics

- Nylon

- Derlin

- Acetal

- Polycarbonate

Plastics

- Peak

- Ceramic

- Tufset

Quantities +

Production

Small to medium batch production is our forte. The components shown above are 100mm diameter ‘hubs’ machined in aluminium. We have the facilities to carry stock, allowing our customers to call off specific quantities when required. Our inventory and tracking system allow us to keep stock for our customers, releasing batch quantities when required.

Fabrication

The component pictured above is a stainless-steel chamber with a TIG-welded ‘union’. The integrity of the weld allows the chamber to be vacuum-tight. In parallel to TIG welding we can also provide the following fabrication services:

- Silver-soldering

- Brazing

- TIG Welding

- MIG Welding

- Sheet Metal Fabrication

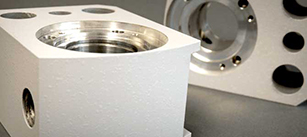

Finishing – Paint

Industrial paint finishes for any specification can be undertaken. The aluminium precision bearing housings pictured above have a tough-baked ‘spatter’ finish, giving long-life durability in harsh environments. This component also illustrates the accuracy to which any given paint finish can be masked before painting.

Other paint finishing services that we can provide include:

- Powder Coating

- Enamel

We can also provide the following pre-finishing services prior to painting:

- Shot Blasting

- Bead Blasting

- Vapour Blasting

- Straight Graining

- Rumbling

Finishing – Plating

Following the production of any given component, we can provide a comprehensive spectrum of plating processes. The component pictured above has been chrome plated.

We can also offer the following plating services:

- Nickel

- Electroless-Nickel

- Chrome (Polished or Satin)

- Alochrom

- Zinc

- Passivate (Clear or Yellow)

- Chemical Blacking

- Anodising (All Colours)

External Resourcing

With our extensive list of connections and founded relationships within the industry, we can provide a fully comprehensive service. If we cannot complete a section of a project, we know someone that can. Illustrated above is an example of some gears that were externally ground and managed by our firm. We can also provide the following services:

- Laser Cutting

- Broaching

- Gear Cutting

- Fabrication

- Assembly

- Spark Eroding

- Grinding

XR1000 Hardinge Bridgeport

Machining Centre

with simultaneous 5- Axis Nikken 350ZA table.